Check out this New York Times article on new treatments to defeat hemophilia.

https://www.nytimes.com/2018/08/13/health/hemophilia-gene-therapy.html

Throughout the U.S., Canada and Europe, plasma centers provide source plasma that can be manufactured into life-saving drugs and produce patient therapies, through a process called plasmapheresis. In plasmapheresis, source plasma is separated and collected from the other components of human blood. The plasma is collected from a voluntary donor and stored onsite in state-of-the-art refrigeration units until it is shipped out for fractionation. The other components of whole blood: red blood cells, white blood cells and platelets, are then returned to the body of the donor.

Modern plasma production technology remains largely based on the manufacturing process known as fractionation, in which proteins are separated to create specific therapies. Plasma protein therapies – also known as PPTs – are individualistic, biologic medicines used to treat burns, shock, trauma and a variety of diseases and disorders, including:

With the core plasma fractionation technology being unchanged for roughly 70 years, there is a solid foundation to the industry. Plasma cannot be synthetically manufactured or produced, so it is vital that healthy and willing volunteers continue to donate.

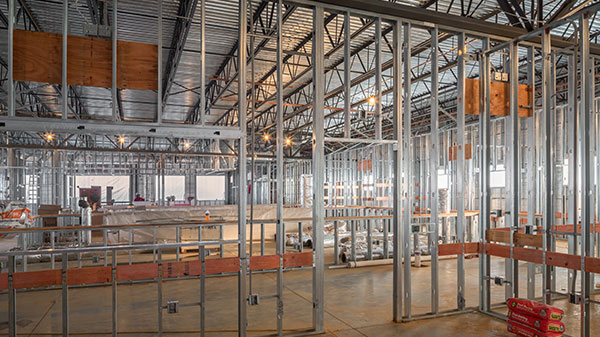

At Stough Group, this foundation sets the standard in our development and design of plasma centers. The designers at Barbara Stough Interiors work to create a space with donor comfort and employee safety in mind. Creating a layout that is welcoming, comfortable and clean ensures patient satisfaction and return. A space that is warm and inviting will improve a center’s productivity, boosting employee morale from the minute they step into the center to when they leave.

Strategic planning sessions are a 20-year tradition at Stough Group. Each year a small group of participants travel to Meeteetse, Wyoming, to take an in-depth look at our company’s goals and objectives, and to explore opportunities for improvement. These meetings are immensely valuable to our company’s growth and development. This year’s task for the team-building exercise was to build a wall tent. I’d say the end result was a SUCCESS! Job well done, guys! Check out some photos from this year’s event at the Wood River Ranch.

True cost of ownership is the cost of buying and maintaining a building. The industry standard for determining the true cost of ownership is the Life-Cycle Analysis. For example, let’s explore the true cost of ownership of VCT versus Vinyl Sheet Flooring over the life of each material.

Due to its durability and design variety, vinyl sheet flooring has become more popular in recent years. Vinyl Composition Tile (VCT), a mainstay in the industry for decades, costs less to install than vinyl sheet flooring, but has a higher life-cycle cost.

VCT has the following issues:

Vinyl sheet flooring avoids all these issues and has superior appearance, durability and longer life.

The following chart provides a brief comparative analysis of the cost of VCT versus vinyl sheet flooring over the life cycle of each product and can be a useful tool for developers and design professionals when specifying materials for a plasmapheresis center. The scenario assumes installation of 10,000 Sq. Ft. of product, in a lease space with a 15-year term. Averages were used for initial installation costs but will vary by market. Given this scenario, higher maintenance efforts and replacement costs ultimately increase the cost of VCT over the life-cycle of the product.

| VCT | Vinyl Sheet | |

|---|---|---|

| Square Feet | 10,000 | 10,000 |

| Installation Cost/Sq. Ft. | $2.65 | $6.03 |

| Initial Capital Cost | $26,500.00 | $60,300.00 |

| Life Expectancy of Product | 10-15 | 20-25 |

| Term of Lease | 15 Years | 15 Years |

| Expected Replacement Cost Through Term of Lease | $51,100.00 (Factors in 4% Inflation and Disposal/Salvage Costs) | $0.00 |

| Maintenance Option | High | Low |

| Total Maintenance Effort Hours and Materials Per Year | 1,584* | 936** |

| Total Hourly Maintenance Rate - Labor, Equipment and Supplies | $35.00 | $35.00 |

| Total Maintenance Cost for 15 Year Lease Term | $981,600.00 | $491,400.00 |

| Total Life Cycle Cost | $1,059,200.00 | $551,700.00 |

| *Includes dust mopping daily, damp mopping daily, spot cleaning/scrubbing and buffing weekly, stripping and waxing quarterly. | ||

| **Includes dust mopping daily and damp mopping daily. | ||

In our example, clients may be attracted to the initial cost savings associated with VCT flooring. However, the cost to maintain VCT is double the maintenance cost of vinyl sheet flooring over the total life of the product.

Life- cycle analysis is paramount to understanding true cost of ownership. At Stough Group, we utilize this perspective to inform our development practices and to ensure that our clients are the beneficiaries of thoughtful design, quality construction, and ultimately, the lowest cost.

For more information on resilient sheet flooring and to view available products, please visit https://www.manningtoncommercial.com/products/hard-surface/resilient-sheet/

To streamline delivery and control costs, we take a prototype approach when possible, engage local civil engineering consultants for each project, and establish a working relationship with the local governing authority.