When he first started at PlasmaCare in 1969, Michael Stough worked in a poorly-lit office at the back of a grubby facility in a rough neighborhood.

Then he got involved in construction for the company, watching drivers of the industry advance collection concepts over the decades. Today, Stough Group’s purpose-built, free-standing centers have taken that evolution to the next level.

THE STOUGH APPROACH:

Partner with us in continuing to improve the plasma business. Call today to discuss your next new facility.

1. Enhancing plasma’s image, production and profitability

As he became more and more involved in plasma center construction and operations, Michael started to believe he could change the image of the industry, enhance production and raise profitability.

He looked at what the most forward-thinking, best-run collection companies were doing:

• Plasma Alliance, led by Dr. Nelson of Knoxville, was one source of inspiration. One of Nelson’s associates told him early on, “You could make a lot of money here.” Nelson responded, “No, we want to be the best.” He trusted that if the goal was highest quality, profitability would follow, and it did.

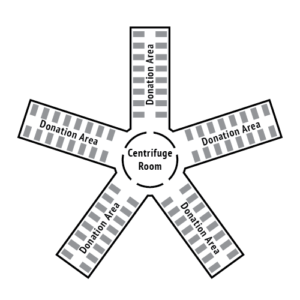

Here’s just one example of how Nelson’s attention to quality went down to the smallest detail: he created a new center design, with the Centrifuge Room as a hub in the middle and Donation Areas as spokes around the hub.

This was not the least expensive design, but in the long run, it was the most cost-effective thing Nelson ever did: it saved hours and miles of walking for the staff, making production safer and more efficient. When competitors could process 600 donations a week, Nelson could process 2,500. His investment in a radical idea led to financial success.

Another quality breakthrough of Nelson’s involved transportation. He bought his own refrigerated trucks to transport plasma, because there was no consistency at the time for keeping it at a safe temperature for preservation during transit.

• Another example of new ideas that rose out of visionary thinking: a Texas company led by Dr. Radding created a playroom for donors’ children and hired child care professionals to staff it. This was a brilliant idea, because centers have fixed costs. If they can see more donors, they make more money.

An industry-wide definition of quality is what percentage of donors are women. When there are more female donors, centers are cleaner, the waiting area is more appealing, and there is less profanity. The childcare center enticed women donors to Dr. Radding’s centers, improving plasma quality, overall operational quality and profits.

• A third example, of particular inspiration to Michael, was Baxter, part of American Hospital Supply, which built the first free-standing plasma collection facilities. They earned a reputation for the best quality AND came to lead the industry in production. They placed centers in small towns, where there was no competition to steal their donors or sully their excellent name.

From these innovators, Michael saw that striving to be the best meant going “all-in”— reaching for the highest standards in facilities and all aspects of operations.

He began experimenting with free-standing collection buildings in better neighborhoods. He found that prioritizing quality actually lowered costs and improved production.

In 2006, Michael sold PlasmaCare, which allowed him to maintain a constant focus on improving the functionality and quality of plasma facilities.

While much in the industry has changed for the better, Michael feels he has just begun.

2. Why Choose Stough?

If we build for you, you will experience all the positive attributes PlasmaCare enjoyed under Michael Stough’s leadership:

A. A more pleasant environment, which leads to lower turnover of donors and staff. It wasn’t just the buildings that made the difference. PlasmaCare took a people-first attitude that involved treating staff and donors as valuable parts of the operation. The workforce became more stable, which in turn was more welcoming to donors. Donors who felt more welcome returned more often. That led to higher productivity at lower costs.

B. Better neighbors, a heathier donor base, and more female donors. It turned out not to be true that plasma centers had to be in depressed areas to draw donors. A Stough-built center is strategically located to serve an up-and-coming area near a university or medical complex.

It draws a healthier donor base, which reduces the viral marker rate, and more female donors, because women feel safer going to a building with good exterior lighting and adequate parking.

Ideally, the manager of this clean, attractive facility becomes an active part of the community. As an asset to neighborhood, the center is much less likely to get “zoned out” by a city that does not want the crime and loitering associated with the typical center in a failing strip mall.

C. A better reflection on your brand. When your plasma collection facilities are assets to the neighborhood, they reflect positively on your brand. You don’t have to give your centers a different name to hide the fact that you run them. The collection part of your business will enhance, not detract, from your reputation.

But we never rest on our laurels. We continuously innovate and improve, keeping our finger on the pulse of the industry’s evolution.

Back To Top

3. Better for the bottom line

In addition to being more inviting and productive, a new building is better for the bottom line than a retrofit of a space built for another purpose. Here’s why:

• A lower cost of operation and a longer economic life

• Stough lease terms are more favorable, or you can buy

• The buildings are well maintained by a landlord with a vested interest

• The space is built specifically for plasma collection. It is constructed to be adaptable for future design modifications that may be needed due to new collection methods or regulation changes.

4. A brighter future for the industry

Plasma collection is critical to the production of a wide range of pharmaceuticals that save thousands of lives every year. The industry keeps growing, and we have been proud to be part of that growth —along with a higher industry-wide emphasis on quality.

Michael has proven that “best” doesn’t have to be most expensive. It is what delivers the most value. We see a bright future for the industry where that concept becomes universal.

Back To TopWORK WITH STOUGH TO BE THE BEST: ENHANCE YOUR CURB APPEAL, MAKE THE INSIDE OF YOU CENTERS AS WELCOMING AS THE OUTSIDE, AND BECOME AN ACTIVE PART OF THE COMMUNITIES YOU SERVE. FINANCIAL SUCCESS IS SURE TO FOLLOW.

Reach Us

To streamline delivery and control costs, we take a prototype approach when possible, engage local civil engineering consultants for each project, and establish a working relationship with the local governing authority.