As we turn 50, we’re celebrating the many ways Stough Group has helped the industry progress. These advances mean your Stough-built center is uniquely suited to support plasma success.

We know what works in plasma collection, and that knowledge saves clients money in the long run, contributing to their success along the way.

Call today to learn the difference Stough development makes.

1. 1940s: New technology, new industry

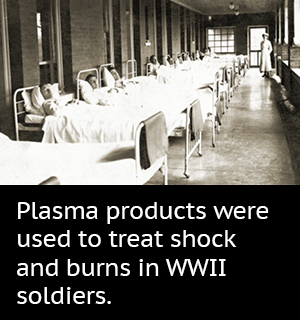

Blood plasma’s history as a life-saver goes back to the 1890s, when blood from horses who had been given diphtheria and then recovered helped humans suffering from the disease. In 1918, the plasma in donated blood was credited with cutting the fatalities of the so-called Spanish Flu in half.

But the commercial plasma industry didn’t get rolling until the 1940s, when Dr. Edwin Cohn of Harvard University invented a fractionation process to separate plasma from blood proteins.

This made it possible to freeze, store and ship plasma economically.

At first, only albumin was isolated to treat WWII soldiers for burns and shock. Over time, additional proteins were separated and used in a wide range of medicines.

Back To Top

2. 1960s: Enter Stough Group

The 1960s were a great time to get into the plasma business. As more and more plasma uses were discovered, vast quantities were needed to produce these drugs at scale.

New drugs required pooling plasma from thousands of donors to create highly-concentrated products. These products required a much larger plasma supply.

In order to support this growing demand, Stough Group opened a collection center in Birmingham, Alabama, in 1965. When that center did well, we subsequently opened centers in several other cities over the next five years.

When the company founder, A.R. Stough, passed away suddenly in 1972, his stepson Michael took over leadership and management.

Back To Top

3. 1970–2005: Growing and improving the model

Michael wanted Stough’s collection operation to become an industry leader in terms of quality and not just profit. He studied innovative competitors, and when named CEO, started on a path to radically change the company’s business model.

The industry was growing quickly with the development of intravenous immunoglobulin (IVIG), subcutaneous administration of immunoglobulin, and the first alpha-1 proteinase inhibitors (A1PI). In 1991, Michael decided it was time to try a different type of collection center.

Instead of expanding into more tired buildings in deteriorating parts of town, we developed new, quality-constructed, free-standing plasma collections centers in up-and-coming neighborhoods.

The experiment was a huge success. That first PlasmaCare building became the prototype for all future Stough expansion. Partly because these facilities made operations more efficient, our costs went down, production went up, and after doubling in size to 15 centers over the next five years, PlasmaCare became one of the top independent plasma producers in America.

Back To Top

4. 2006 to now: Focused on improving the quality of plasma centers

As the industry became vertically integrated, Michael realized competing on price was not his path. Inspired by others and convinced by his own experience, he decided the best way to help the industry was to leave plasma collecting to others, and focus on helping former competitors achieve success through quality facilities.

In 2006, we sold PlasmaCare to Grifols, a plasma leader, which has continued to expand and improve the industry.

It took some time (and the 2009 recession) to convince our new clients of the wisdom of quality-built, free-standing buildings, but by 2013, forward-thinking, quality-minded clients were enjoying the same benefits that had made PlasmaCare a leader:

• Less crime near centers

• Lower viral marker rates among donors

• More female donors

• Less chance of being “zoned out” of locations

• Higher acceptance by neighbors

Because these centers were built by people who knew the business inside and out, clients’ facilities were more productive and easier to maintain than retrofitted spaces, and were a better long-term investment.

Stough Group flourished by serving clients with parallel goals, and today many of the industry’s top players operate out of Stough-built centers.

Back To Top

5. What next?

Since 2006, we have worked to help plasma operators modernize facilities, advance the industry’s image, and improve the process of plasma collection.

Our vision was to change the industry, and that is still our goal under the new CEO, Michael’s son Scott. Gifted in both sales and leadership, Scott is thrilled to bring his own perspective to the Stough mission.

Adding new discoveries to everything we have learned through 50 years in the business, our development team is committed to making each new Stough-designed-and-built center better than the one before in terms of:

• Efficiency

• Surface cleanability

• Ventilation

• Lighting and colors that improve morale/productivity

• Safety

Whether convalescent plasma proves to help people with the novel coronavirus remains to be seen, but whatever challenges the future holds for the industry, Stough Group is here for you.

Back To Top