How air circulates makes a difference in the health of your indoor air, how electrical devices must be rated, and how air-tight your building must be.

While many builders use Flex Duct and plenum returns, we have found metal ducts and ducted returns are best for plasma centers.

1. The purpose of the plenum

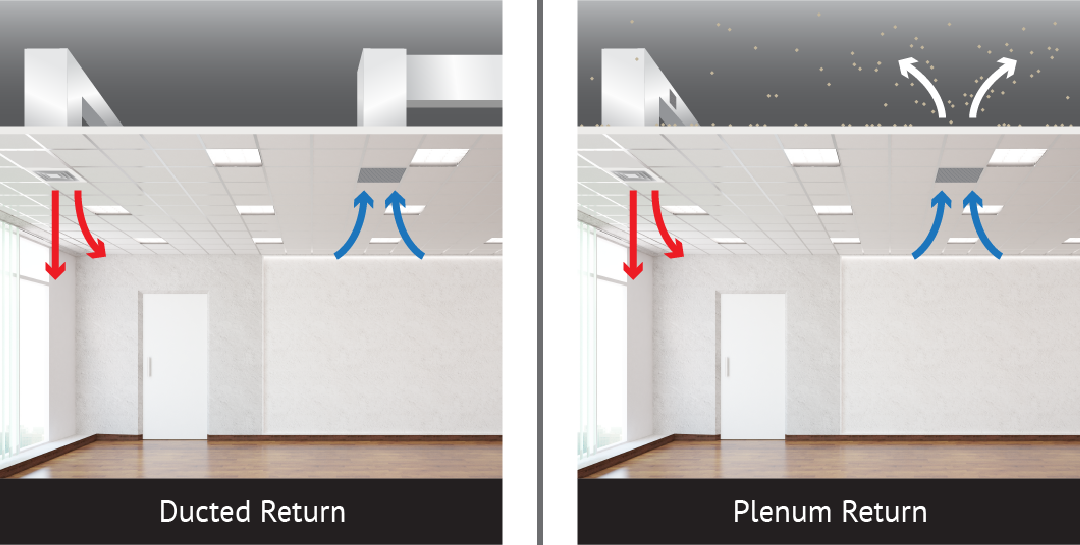

The plenum is the space between the acoustic ceiling and the structural ceiling of a building.

It provides a pathway for cabling and heated/conditioned air. Sometimes air flows through boxes (ducts) inside the plenum; in other situations, it flows directly through the open plenum.

Back To Top2. Why we require ducted air returns

In many commercial buildings, air returns to the furnace or air conditioner via the open plenum (this is called a plenum return). Our buildings always have ducted returns for several reasons:

· With a plenum return, your air travels through the plenum, which can contain particulates, bacteria, viruses and residuals from wire coatings. (The filters on furnaces and AC systems don’t remove many of these contaminants.) Ducted returns are more tightly sealed, so dirt, dust and contaminants can’t get in.

· With a plenum return, all your electrical devices have to be plenum-rated.

· Plenum returns require buildings to be airtight with no leaks.

· If you don’t use ducted returns, the plenum itself has to be heated or air-conditioned to maintain the temperature of the air passing through. Ductwork can be cost-effectively insulated.

Overall, ducted returns in plasma centers are much healthier for donors and employees, and not more expensive in the long run.

Back To Top3. Metal ducts vs. Flex Duct

Metal ducts (also called rigid or hard ducts)

These galvanized steel or aluminum ducts offer a permanent solution to a commercial HVAC system when proper maintenance is performed regularly.

The width-to-height ratio in a commercial building is a consideration. It should provide enough space for metal ducts in order to optimize the energy efficiency and performance of them.

Flexible ducts or Flex Duct

Rubber, PVC, stainless steel, silicone, polyurethane and neoprene-dipped polyester fabric are common types of flexible ductwork material.

Rubber, PVC, stainless steel and silicone are best for commercial buildings in extreme climates. Rubber and polyurethane offer the best abrasive resistance. Silicon can’t handle interior damage during extreme weather.

Flex Duct is easier and faster to install, but leaves more room for contractor error, which can cause high energy bills, excess maintenance or the need for costly emergency repairs and replacements.

Why we think metal ducts are superior

Flex Duct is cheaper in the short-term, but metal is longer-lasting, and saves money in the long-term by maintaining high indoor air quality and effectively regulating indoor temperature, no matter the outdoor climate.

Flexible ducts are a poor compromise in your HVAC system. Metal ducts are a better choice for a new building with an entirely new HVAC.

We exclusively use metal ducts in new construction because there are so many problems with Flex Duct:

· Kinks and sharp turns

· Lengthy and unsupported duct runs

· Radial systems with excess ducts coming off the plenum

· Too-close unmeasured takeoffs

· Extra duct length

· Poorly fastened and sealed connections

· Unsupported butt joints

Metal offers a lower resistance to airflow, and many of the problems listed above are irrelevant to sheet metal’s rigidness. The bows inherent in Flex Duct slow down air velocity as well.

If you have a room that is too hot in the summer and too cold in the winter, it could be because a Flex Duct is kinked and closing off air flow.

Back To Top